- 제품소개

- 3D Printing GMS

- 3D Printer에 안정적인 Gas 공급 및 컨트롤

- Gas 재활용을 통한 원가절감 (2~3년 안에 투자비용회수)

- 3D Printer/Welding Machine 기존장비에 연결가능

- Designed & Made in USA

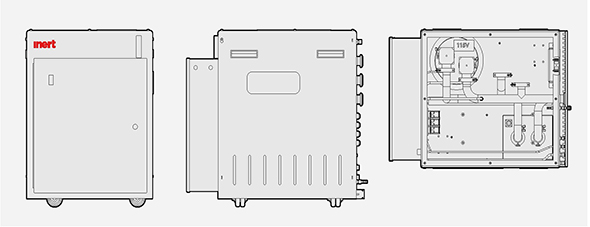

ARGON-1

External Dimensions:

660 mm W x 914 mm D x 813 mm H

SR Models:

Large capacity solvent vapor removal system.

Contents: 7.5Kg activated carbon.

RSR Models:

Regenerable Large capacity solvent vapor removal system.

Contents: 9.5kg molecular sieve.

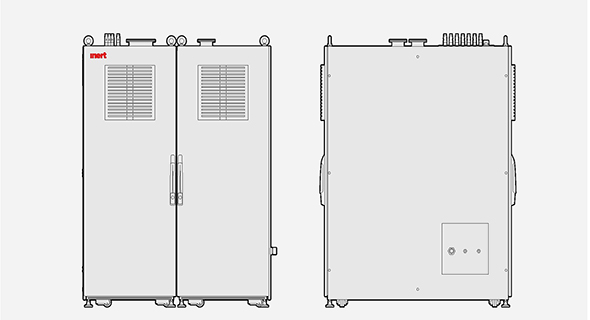

ARGON-10

External Dimensions:

1219 mm W x 1270 mm D x 1575 mm H

SR Models:

Large capacity solvent vapor removal system.

RSR Models:

Regenerable Large capacity solvent vapor removal system.

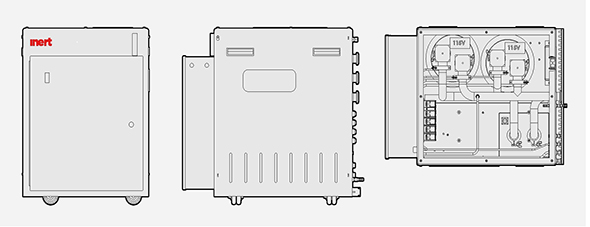

ARGON-2

External Dimensions:

660 mm W x 914 mm Dx 813 mm H

SR Models:

Large capacity solvent vapor removal system.

Contents: 7.5Kg activated carbon.

RSR Models:

Regenerable Large capacity solvent vapor removal system.

Contents: 9.5Kg molecular sieve.

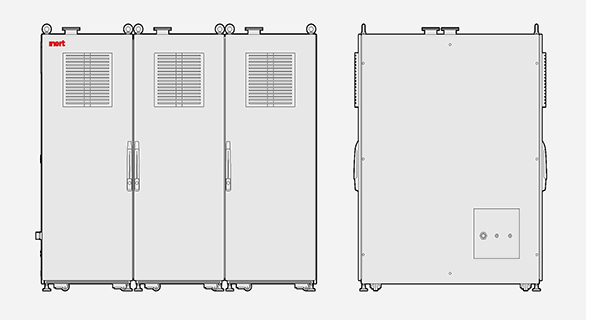

ARGON-20

External Dimensions:

1854 mm W x 1270 mm Dx 1575 mm H

SR Models:

Large capacity solvent vapor removal system.

RSR Models:

Regenerable Large capacity solvent vapor removal system.

SPECIFICATIONS

| External surfaces:RAL 7035 |

| Casters for mobility |

| <1ppm 0, and <1ppm H,0 purity level

When connected to a glovebox system that has a leak rate of <0.05 vol%/h

Argon-1 and -2- All Permutations: O2 capacity = 43L H2O capacity = 1800 g Argon-10 and -20: O2 capacity = 217 L per Purifier Column H2O capacity= 9000 g per Purifier Column |

| Automated purifier column valves:Interlocked with the blower.

Blower will not run if the valves fail to open

|

| Variable speed circulation blower:

Argon-1 and -2- All Permutations:120 cfm max flow rate blower

Argon-10 and -20 - All Permutations:185 cfm max flow rate blower |

| Max flow rate through purifier column:

Argon-1 and -2- All Permutations:60 cfm (101 m/h)

Argon-10 and -20 - All Permutations:(315 m/h) |

| PLC control system |

| 6" color touch screen |

| Trending Screen:Pressure, O2 and H2O Value is logged for 24 hours |

| Automatic pressure control:(+/- 15 mbar) |

| Manual pressure control:Footswitch |

| Fully automatic regeneration sequence |

| Purge valve:O2 Level, Timer or manually controlled |

| Vacuum pump:10 cfm (17 m3/h) rotary vane pump with oil mist eliminator & oil return kit |

| Integrated oxygen and moisture analyzers (sold separately):

Range 0-1000 ppm

Zirconia O2 analyzer as standard, or electrochemical sensor for solvent compatibility |

| Eco Mode Features

Vacuum pump timer:Shuts pump off for energy reduction

Automated Blower speed control:O2 level adjusts blower speed |

OPTIONS

- 0-1000 ppm Zirconia oxygen analyzer (not for use with solvents)

- 0-1000 ppm electrochemical oxygen analyzer (solvent compatible)

- 0-25% zirconia oxygen analyzer

- 0-1000ppm moisture analyzer

- 0-25% Helium in Argon analyzer

- Solvent sensor

- Heat exchanger located in the circulation loop. 1000 W cooling capacity with 18 lpm flow rate of cooling water

- Dry scroll pump

- Solvent removal system

SYSTEM APPLICATIONS

- Additive (3D) Manufacturing

- Aerospace

- Automotive

- Chemistry

- Lamp Manufacturing

- Lithium Ion Battery

- Medical Device

- Nuclear

- OLED

- Pharmaceutical

- Semiconductor

- Solar

- Specialty Chemical

- Thin Film

- Many other applications